Whether plastic or metal, whether individual marking or series marking – with our marking system you will always find an optimal and at the same time economical solution for every task. With MultiCard, MetalliCard, MultiMark, or CableLine you make the right decision. Our marking systems are designed to deliver precise and durable results that meet high quality standards. The marking of cables, products or control cabinet components ensures easy identification and traceability to optimise operational processes. Rely on Weidmüller’s high-quality products – for more efficiency and precision.

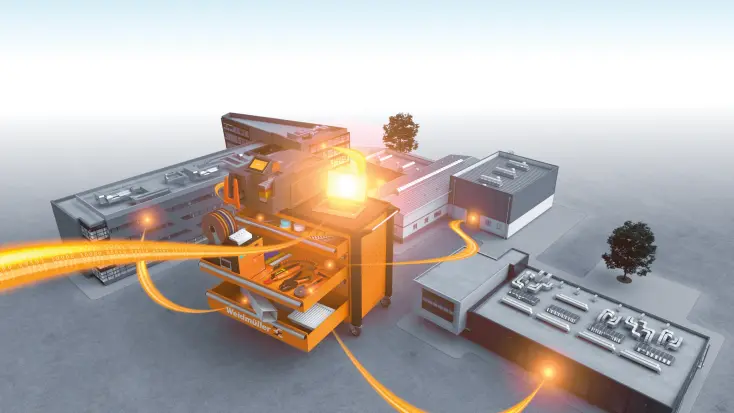

We offer you a comprehensive approach for industrial labelling systems. The printer, software and marking systems form a coordinated unit. The industrial printer is the focus and produces high-quality, durable markings. Specialised M-Print® PRO printing and ordering software makes it possible to quickly and easily create custom markings. Weidmüller’s marking systems are designed to harmonise perfectly with the industrial printing systems and software.

The M-Print® PRO software for our industrial labelling systems impresses with its intuitive usability tailored to your specific needs. The software’s quick and easy import as well as the easy editing and management of data promote efficient marking processes.

Our marking solutions offer you constructive solutions for all applications around the control cabinet. No matter whether you want to label shrink sleeves, metal markers or other materials – we have the right, high-quality solution for you. Optimise your panel building with marking systems for industry.

With our industrial printing systems you have the choice between ink, thermal transfer and laser technology. Permanent and high-resolution labelling is possible without complications with the industrial printers as part of the marking system.

With our marking systems, you can handle almost any labelling task. The labelling systems are suitable for labelling control cabinet components and other electrical components. Our terminal markers are characterised by their high shock and vibration resistance.

We support panel builders around the world and understand the challenges they face. We therefore provide you with sophisticated products and solutions of excellent quality for every step in panel building. This is how we create added value for you and your customers. Take advantage of our know how.

Do you have questions about our products and services or would you like an individual offer? Simply fill out contact form. Our employees will contact you as soon as possible.