Bipolar plates are the heart of electrolysers used to produce hydrogen. Depending on the manufacturing process, stacks can consist of hundreds of such bipolar plates, whereby a single defective plate can negatively impact the performance of the entire stack. Because of this, it makes sense to monitor the voltage of each plate separately. We have developed the appropriate solution for this and thus the measured values can be recorded and processed reliably, safely and economically in potentially explosive areas.

Experience our end‑to‑end approach to stack monitoring. From cell pickup to data acquisition, communication and real‑time analysis.

Cell voltage measurement for stacks: electrolyser, fuel cells & BESS

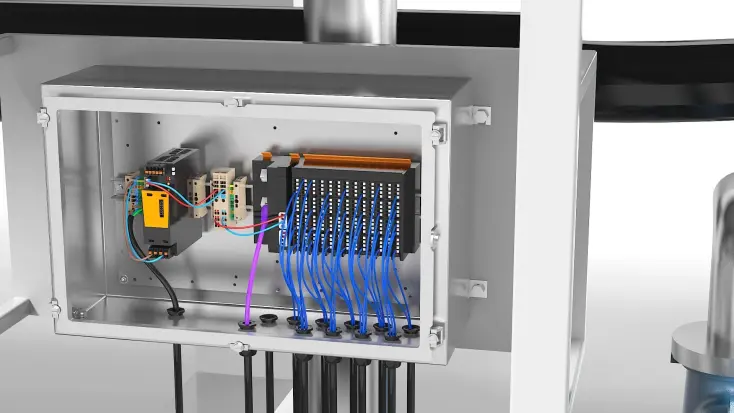

Our Cell Voltage Measurement Box (CVM) enables safe stack condition monitoring in hydrogen systems. It enables the differential voltage measurement of individual cells for electrolysis stacks, fuel and battery cells for data collection and analysis. It is compatible with manufacturer and fulfils all customer requirements in the hydrogen industry, including the necessary certifications.

This is a YouTube video. By clicking on this video, you agree to Google/YouTube's Privacy Policy & Terms of Use . You also agree to our Privacy Policy.

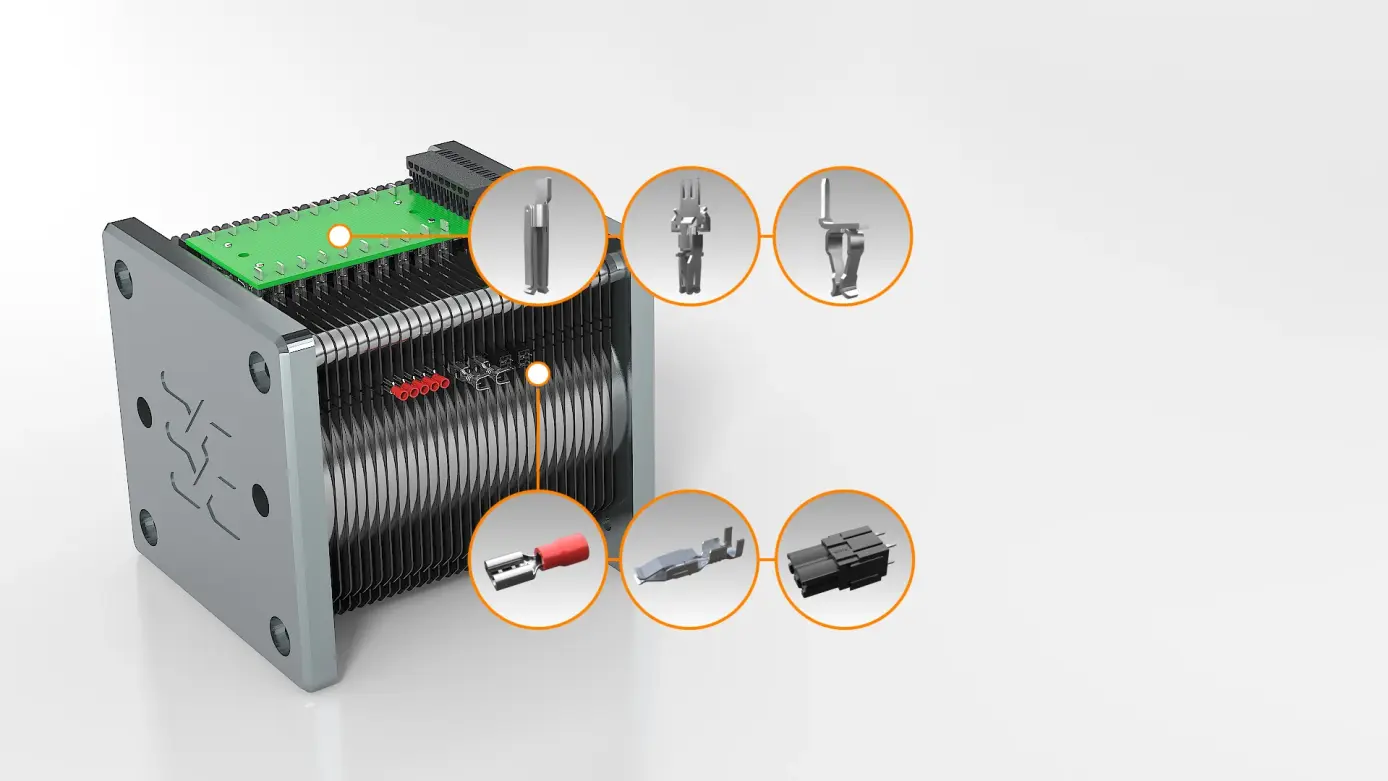

In addition to individual contacts, customised designs are also possible. The contacts are assembled onto an interface board, enabling multiple contacts and, if necessary, fuse protection. The temperature-related expansion and the manufacturing tolerances of the stack must be taken into account. Compared to individual contacting, the interface solution offers considerable time savings and error reduction in stack production.

Data acquisition is accepted by the u-remote station with Ex approval for Zone 2. The data is forwarded to a gateway or router. For connection to the control system, we provides variants for all common fieldbus protocols like PROFINET, Modbus TCP and of course Ethernet.

In addition to the LAN connection, a connection via IoT-boxes to the customer's cloud or our own cloud is also possible. This enables remote access to stationary systems. In addition to the plant operator, the stack manufacturer can also access the plant remotely for diagnostics, service and support purposes. This serves the purpose of preventive maintenance and maximises the operating time of the system.

With our visualization hardware and software solutions, we enable real-time data acquisition from stacks, empowering manufacturers and operators to monitor crucial parameters and identify potential failures like cell degradation, gas crossover, leaks, sealing issues, and stack contamination. Our integrated approach guarantees a seamless flow of data from the stack to the cloud, which can be used for automated machine learning.

By integrating edgeML into PROCON-Connect, the results of the models can be transmitted to HMI and SCADA applications, for example, where they can trigger alarms or be transferred to the cloud of operators and manufacturers via MQTT

Weidmüller takes advantage of its many years of experience to approach the newly forming climate-neutral energy landscape, combining its activities under the area of “New Energy”. In order for you to make the best possible decision for your plans, you should of course be fully informed. For example, plan a comprehensive decarbonization with our extensive product range. From the Cell Voltage Monitoring (CVM) for fuel cells to the Photovoltaic solutions customized solutions can be implemented. From initial sampling to series production, Weidmüller accompanies you and thus enables the customer-specific development of electrical and electrotechnical solutions for hydrogen plants. With many years of experience and great commitment to the industry, we offer products for the digitization and modularization of hydrogen plants that meet all requirements.

As a pioneer in industrial connection technology, Weidmüller combines expertise gained over many years in wind energy and photovoltaics with its competence in process engineering. This allows the company to integrate its extensive expertise from maritime applications, power to X and DC technology with the new energy landscape. In order to provide you with sufficient information about our products, we provide you with our documents on topics such as the industrialization and digitalization of hydrogen plants. With the portfolio overview, you have collected all the details you need to find ideal solutions for your project.

Whether hydrogen production, storage or processing - our hydrogen plant solutions meet all requirements. With many years of experience and extensive know-how, we convince with high-quality products. Let our experts in the fields of contact technology, electronics and automation advise you and trust in our competence as pioneers for the challenges of the future. Together, we lead your project to success with the right products for modularization, digitization and industrialization of hydrogen plants.

Cengiz Oguzoglu

Global Business Development Manager Hydrogen