Crimping is a process for securely joining two components by pressing, which has largely replaced soldered joints.

Crimp defects must be avoided in order to achieve high-quality crimp connections. This requires manual skills as well as matching tools and wire-end ferrules. Various international norms and standards, some of which reference each other (e.g. DIN 46228, Part 1+4, DIN EN 60999-1, DIN EN 60352-2), are crucial to ensure the quality of a crimped connection with regard to tensile strength and fault prevention.

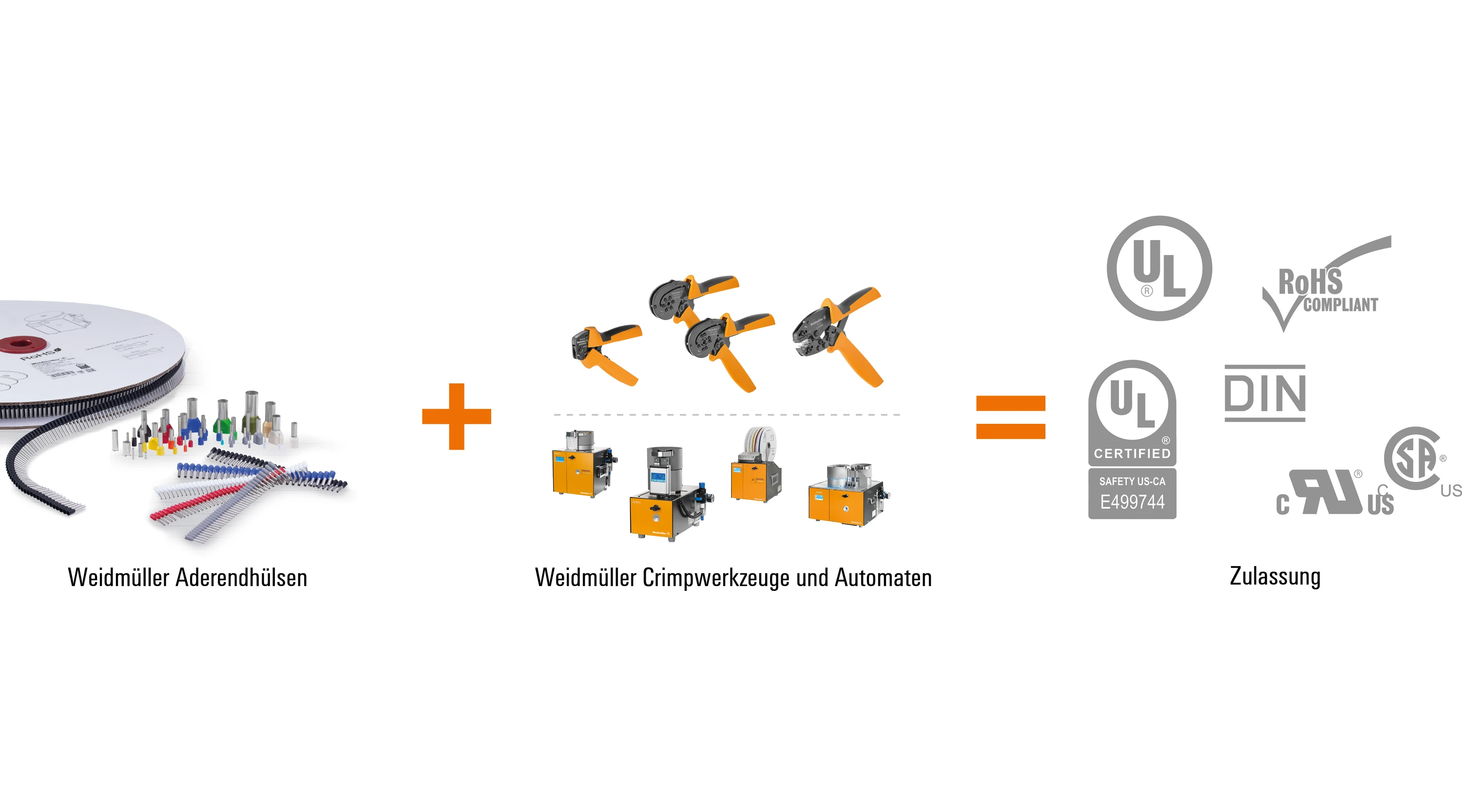

UL approval differs from conventional standards because, as it is issued after extensive testing in dedicated test laboratories. Wire-end ferrules are always tested as part of a system along with their processing tool according to UL 486 F and receive a joint approval. End users can test whether their materials are certified in the UL online certification directory: (https://productiq.ulprospector.com/de ). The E number for Weidmüller hand tools and crimping machines in combination with wire-end ferrules is E499744. UL 486 F standard closely follows the German DIN 46228 standard.

DIN 46228-1/4 defines the requirements and test methods for wire-end ferrules and their use. Part 1 covers wire-end ferrules in tubular form without plastic collar, while Part 4 contains specific requirements for wire-end ferrules in tubular form with plastic collar. The standard specifies the materials, dimensions and properties that the ferrules must possess in order to ensure a safe and reliable connection. It plays an important role in quality assurance for electrical installations. Compliance with this standard is the responsibility of the manufacturer or operating company. There is no central supervisory authority.

Do you have questions about our products and services or would you like an individual offer? Simply fill out contact form. Our employees will contact you as soon as possible.